Tooling Solutions

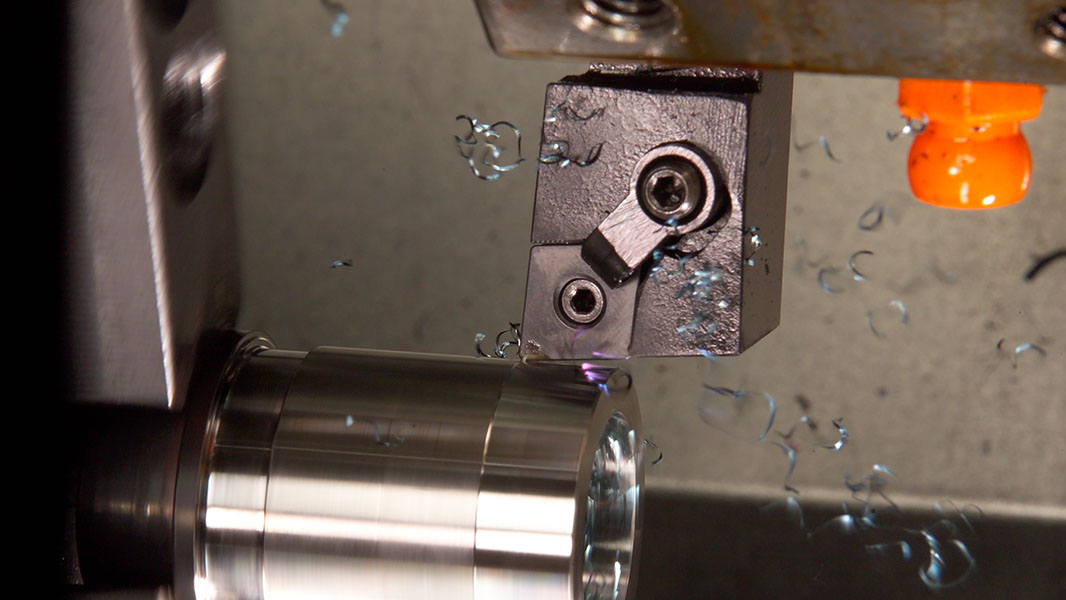

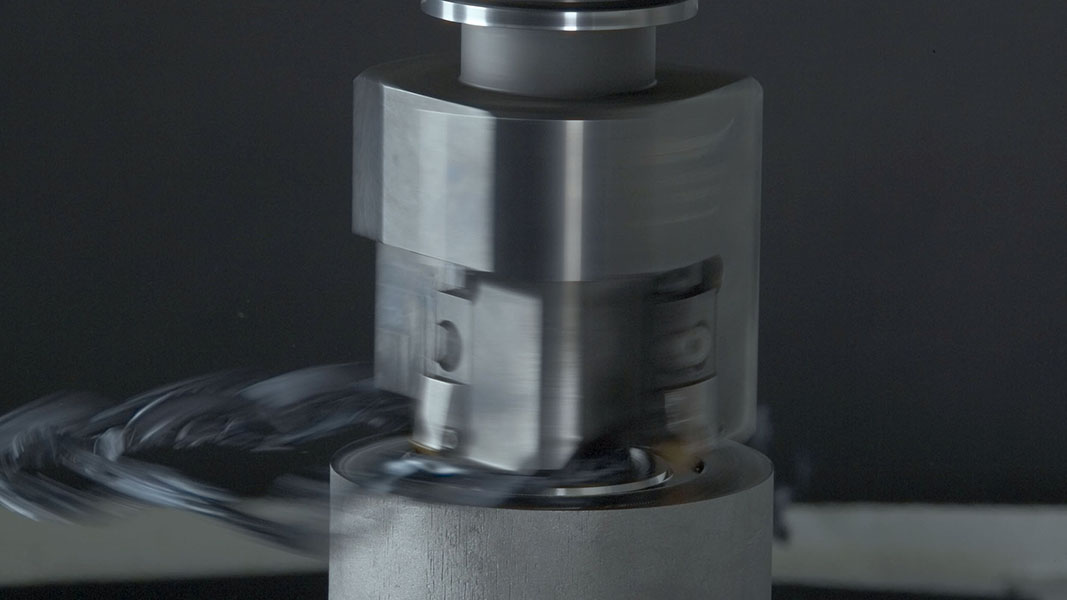

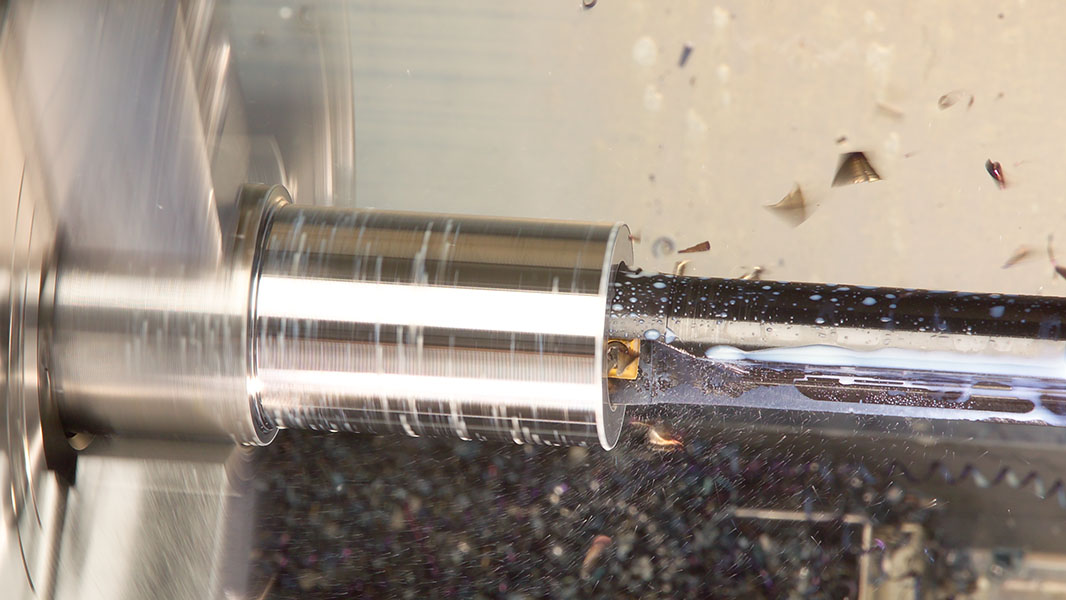

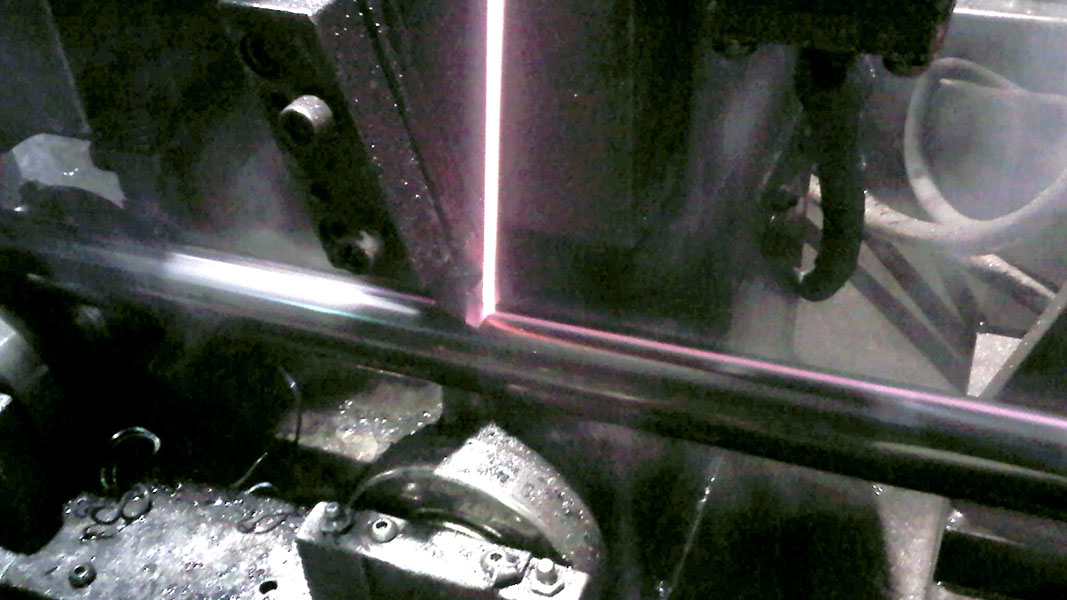

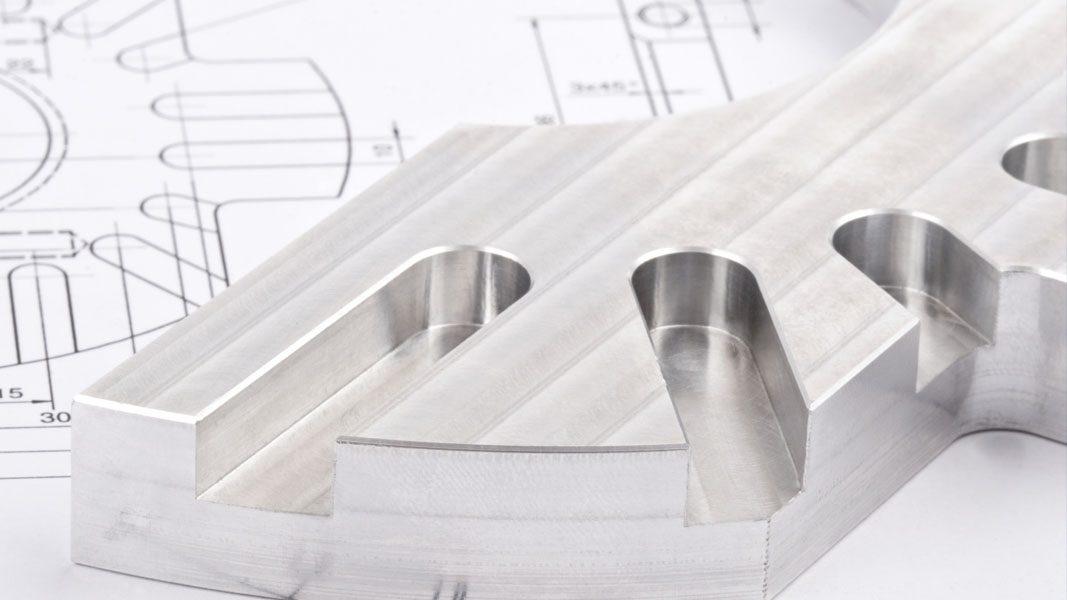

Greenleaf’s products are engineered to provide optimal performance against a wide range of materials under the most rigorous metal-cutting conditions. In addition to specially engineered tool-holding systems and a comprehensive line of carbide inserts, Greenleaf offers high-quality ceramic and ceramic composite materials, which can be custom designed for specific machining applications.

Our complete metric and imperial catalogs are available for online viewing and downloading for offline use.